Geopac PLX

DESCRIPTION:

AT-GEOPAC PLX is a unique anionic polymer developed for application as earth stabilizer slurry. It offers a multitude of advancements and improvements over conventional mineral based slurry technology (Bentonite). It is of high molecular weight, long chain synthetic polymer containing numerous negatively charged sites distributed across their backbones.

ADVANTAGES:

- AT-GEOPAC PLX provides the following beneficial properties

- Small quantity required

- Controls fluid loss in sand and gravels

- Increases safe load capacity of pile through higher skin friction compared to bentonite

- Facilitates in quick settlement of fines coming out with bored soil and maintains clear fluid

- Doesn’t change pH of soil

- Does not affect concrete to reinforcement bonding

- Improves productivity of machines & manpower by reducing the cleaning of machineries

- Requires less mixing time, reducing cost, job site congestions and fuel cost

- Doesn’t lose its effectiveness even when mixed with bentonite

- Reduces disposal hazards and cost

- Reduces storage area requirement and hence cost

- It is not only environmentally safe compared to bentonite, it creates a dust-free and sticky mud-free environment in the site and readily bio-degradable

- Lubricates excavating tools, lessens friction and wears

- Environment- friendly and safe

- Harmless to aquatic organisms, wild life and human life

- Non-combustible

- Bio-degradable

BROAD APPLICATIONS OF AT-GEOPAC PLX:

- Can be used in areas that contain high amount of fine silt, clay, colloidal soils, to establish stability of slope

- It is used to stabilize bore holes of piles, trenches, diaphragm walls

- Can be used to stabilize low height vertical shoring and embankments

HOW IT WORKS:

- AT- GEOPAC PLX Polymer is mixed with fresh water; its long polymer chain uncoils and creates thick viscous slurry. This uncoiling creates a strong bond that cohesively binds the excavated soil solids & facilitates their removal from excavation. On the other hand, through mixing with the surrounding turbid water, the dissolved polymer attaches them to soil particles & forms a bond which binds the soil and polymer particles into a larger mass. It leads to rapid settlement of suspended sediments from the water column and lastly with its long string creates a thin impervious barrier on the surface of the formation hole. As the water dissipates from the soil or aggregate, a durable water resistant matrix of flexible solid mass is created.

MATERIAL DATA SHEET:

| MATERIAL NAME | AT-GEOPAC PLX |

| CHEMICAL NAME | Long chain synthetic polymer, copolymer of acrylamide anionic |

| CHEMICAL DESCRIPTION | Viscous liquid |

| MANUFACTURER | ADO ADDITIVES MFG PVT.LTD |

| PRODUCT VERIFICATION | Construction Engineering Department, Jadavpur University |

| TOXICOLOGICAL INFORMATION | No adverse effect on human heath |

| SPECIFIC GRAVITY | 1.02 + 0.005 at 300 C |

| COLOR | Translucent |

| ODOR | Odorless |

| SOLUBILITY | Soluble in water |

| PH | 8.5 + 1 |

| CHEMICAL STABILITY | Stable at normal conditions |

| SHELF LIFE | One year |

| POSSIBILITIES OF HAZARDOUS REACTIONS | No |

| COMBUSTIBILITY | Non-combustible |

GUIDELINE AND CRITERIA (according to ACI. 336R. 91)

| AT-GEO PAC PLX GUIDELINE AND CRITERIA | |

| VISCOSITY (sec) | 32-45 |

| DENSITY(NEWLY MIXED) | 1.00~1.055 |

| DENSITY(AT EXCAVATION) | 1.00~1.055 |

| DENSITY(REPEATED USE) | 1.00~1.055 |

| pH VALUE | 8-12 |

| pH VALUE (REPEATED USE) | 8-12 |

| SAND CONTENT (AT EXCAVATION) | under 1% |

| SAND CONTENT (AT POURING) | under 1% |

| SAND CONTENT (REPEATED USE) | under 1% |

DOSAGE:

- 0.5% – 2% by weight of water depending upon the soil characteristics.

GENERAL GUIDELINE FOR USE OF AT-GEOPAC PLX: It is advisable to conduct advanced survey on the construction site’s soil structure and state of distribution prior to formal implementation and have adequate stabilizer liquid materials and mixing ratio ready. The following guidelines are provided from past experiences:

- It is imperative to keep the inert hydraulic pressure 1.5 m or higher than the ground water table.

- When working on general grounds, the stabilizer liquid’s viscosity should be 30-35 secs.

- When working with sandy and softer grounds, the viscosity should be 35-45 secs.

- For pebbles, the viscosity should be more than 45 secs.

- The stabilizer liquid pool and condensation pool should be at least 1.5times of the largest segment in the site.

- Throughout the implementation period, the supply of tap water should be in abundance.

- When working on sandy grounds and with the ground water table being very close to the ground surface, to prevent hole collapsing beneath the guide trench, it is advisable to dig a strategic well in advance, and have the water table lowered.

FORMULA TESTING:

Upon concluding mixing the stabilizer liquid, viscosity and pH rating tests would help to discern whether the formula has reached the implementation criteria: if not, follow the following means to improve it:

- When the pH rating exceeds the criteria, add water to moderate the formula within the specified criteria

- When the viscosity falls below the criteria, add an adequate amount of AT-GEOPAC PLX to bring up the concentration

- When the viscosity exceeds the criteria, add water to moderate the formula within the specified concentration

COMPARISON BETWEEN BENTONITE AND POLYMER-BASED SLURRY IN APPLICATION

| DESCRIPTION | BENTONITE SLURRY | POLYMER-BASED SLURRY |

| MATERIAL CHARACTERISTICS | Natural montmorillonite that comes in a minute powder form, and requires extended time to fully dissolve in water. | High molecular polymer which expands completely in water within a relatively shorter time. |

| OPERATING CONVENIENCE | A longer soaking time due to a larger volume sued. | A relatively small soaking time is required. |

| MAIN FUNCTION IN BORE HOLE STABILITY | Unit weight (density) and filter cake effect | Unit weight and binding of soil particle by polymer strand. |

| BALANCE | It increases alongside aggregated viscosity and sand content. | It weighs slightly more than water for its mud-free balance at over 1.00. |

| RECALL AND REUSE | Its recall and reuse is tied to screening the water quality; in general, reprocessing is required when the recycled water contains a large amount of mud and severe water quality deterioration would require the formula be scrapped. | The recalled fluid is clear and free of mud, and only requires replenishing the AT-GEOPAC PLX polymer and adjusting its viscosity and pH value for reuse without scrapping to greater conserve of water usage. |

| SIMPLIFIED CONTROL | As ground structure varies, it however requires adding a variety of accelerants, and varied mixing also makes the inspection work fastidiously and difficult to co-ordinate. | It merely requires checking the viscosity and pH value, making the inspection work simple and easy to co-ordinate. |

| LOW COST | Though with lower direct cost, yet the subsequent waste water processing cost and sludge transport could constitute a large expenditure, let alone the significant cost in post excavation wall repair. | Though with a slightly higher direct cost, it is nearly free of any subsequent problem to greatly excel its added value, conserve significant expenditure, and improve the projects profit margin. |

| ENVIRONMENTAL IMPACT | Particulate nature, potentially hazardous to aquatic life and not be disposed in drainage system or sewers | Non-particulate nature, non-hazardous and can be disposed on site in drainage system or sewers |

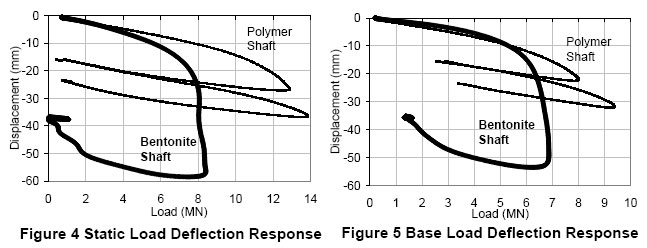

ADDITIONAL ADVANTAGE OF POLYMER SLURRY FOR IMPROVING AXIAL LOAD CAPACITY OF PILE Two instrumented test shafts

FOR IMPROVING AXIAL LOAD CAPACITY OF PILE

Two instrumented test shafts were constructed under identical conditions except for the use of bentonite drilling slurry in one shaft and polymer slurry in the other. The results of the load testing program indicate a threefold increase in side shear resistance in the dense silty sands for the shaft constructed with polymer over that of the shaft with bentonite. This difference is thought to be due to improved bond at the shaft/soil interface. The base resistance was also higher for the polymer shaft, although the difference appears to be larger than can be logically attributed to improved bond at the interface.

HEALTH & SAFETY:

- Protect hands with rubber gloves and eyes with goggles.

- Accidental splashes to the skin or eyes must be rinsed immediately with clean water.

- Store in well-labeled containers.

- If required get medical attention.