Exobond

DESCRIPTION:

AT-EXOBOND is a solvent-free, two component bonding agent, based on selected epoxy resins. It exhibits unique versatility feature both in respect of product application and performance. The system consists of a resin and a hardener that can be formulated to offer wide range of mechanical, thermal, optical and electrical properties. While mix ratios differ, they all offer the ability to cure at ambient temperatures or at elevated temperatures for faster cures.

STANDARDS:

AT-EXOBOND 120 compiles with ASTM C 881-78 type II, Grade 2 Class B+C

ADVANTAGES:

AT-EXOBOND a two part epoxy adhesive system can produce assemblies mechanically equivalent to or stronger than conventional metal fastened parts at a lower cost and weight. They also offer:

- Resistance to vibration and shock

- Ability to withstand thermal cycling

- Fast cures at ambient temperatures

- Gap filling capability

- Exceptional adhesion to similar and dissimilar substrates

- Uniform stress distribution

- Long-term durability

- Easy application

- Solvent free formulation

- Dimensional stability

USES:

AT-EXOBOND exhibits bond strength that is greater than the tensile strength of the concrete. Therefore it is suitable for use as a structural bonding agent for:

- New to existing concrete

- Mortar

- Steel, Iron

PHYSICAL PROPERTIES:

| FORM | Thick Liquid |

| COLOUR | Comp A: White ; Comp B: Brown ; After mixing – Light Yellow |

| MIXING RATIO | Comp. A : Comp. B = 2 : 1 by weight |

TECHNICAL PARAMETERS:

| CHEMICAL BASE | Epoxy Resin |

| DENSITY | 1.70 kg / l (Comp. A + Comp. B when mixed) @ 27°C |

| CHANGE IN VOLUME | Shrinkage / Creep: Hardens without shrinkage |

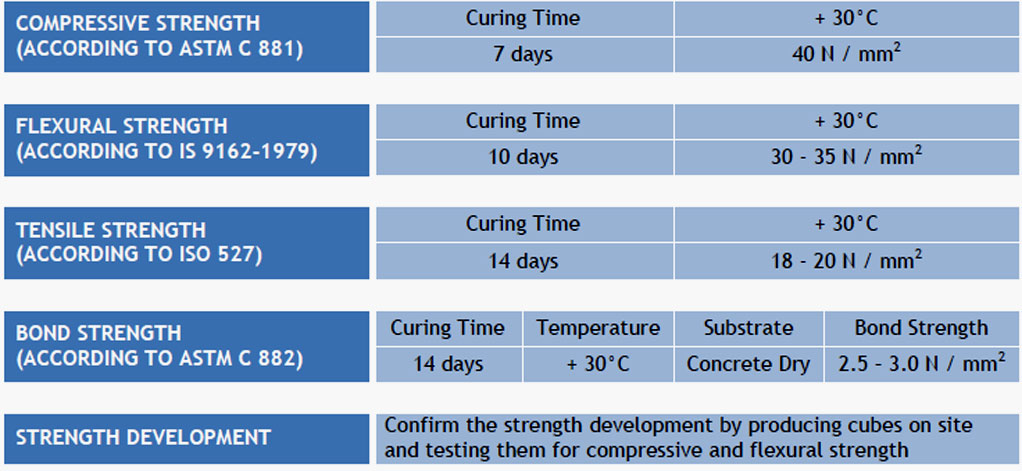

MECHNANICAL PROPERTIES:

SYSTEM INFORMATION: APPLICATION DETAILS:

| SUBSTRATE QUALITY | Mortar and concrete must be older than 28 days (dependent on environment & strength). Verify the substrate strength (concrete, mortar). The substrate surface (concrete, mortar) must be clean & free from frost standing water. Steel substrate must be de-rusted similar to Sa 2.5. Concrete substrate must be sound and all loose particles must be removed. |

| SUBSTRATE PREPARATION | Concrete / Mortar: Substrates must be sound, dry, clean and free from laitance, ice, standing water, grease, oils, old surface treatments or coatings and all loosely adhering particles to achieve a laitance and contaminant free, open textured surface. Cement laitance must be removed and the surface to be treated must be mechanically roughened Steel: Must be cleaned and prepared thoroughly to an acceptable quality i.e. by blast cleaning & vacuum. |

APPLICATION INFORMATION:

| MIXING | Component A : Component B = 2 : 1 (by weight) |

| MIXING TIME | Pre-batched units Mix parts A+B together for at least 3 minutes with a mixing spindle attached to a slow speed electric drill (max. 600 rpm) until the material becomes smooth in consistency and a uniform YELLOWISH colour. Avoid aeration while mixing. Then, pour the whole mix into a clean container and stir again for approx. 1 more minute at low speed to keep air entrapment at a minimum. Mix only that quantity which can be used within its pot life. |

| APPLICATION CONDITIONS / LIMITATIONS | After mixing, apply directly to the prepared substrate by brush, roller. On damp surfaces, ensure that it is well brushed in. Pour the mixed material within the gaps hole continuously during fixing road signals. |

| COVERAGE | 0.3 – 0.8 kg/m2 , depending on substrate condition |

| POT LIFE (ACCORDING TO EN ISO 9514) | Temperature | AT-EXOBOND |

| 30°C | 25 min | |

| The pot life begins when the resin and hardener are mixed. It is shorter at higher temperatures and longer at lower temperatures. The greater the quantity mixed, the shorter the pot life. To obtain longer workability at high temperatures, the mixed adhesive may be divided into portions. Another method is to chill parts A + B before mixing them (not below + 5°C) | ||

| OPEN TIME | Temperature | AT-EXOBOND |

| 30°C | 50 min |

NOTE: All Technical Data stated in this Product Data Sheet are based on laboratory tests. Actual measured data may vary due to circumstances beyond our control.

PACKAGING & STORAGE:

- AT-EXOBOND is available in the following system pack

- 10 kg & 5 kg (HDPE container)

- Shelf life is 12 months in sealed containers as provided

- Keep containers sealed and away from heat and cold in a well ventilated area

- Stir material well before use

HEALTH & SAFETY:

- Protect hands with rubber gloves and eyes with goggles.

- Accidental splashes to the skin or eyes must be rinsed immediately with clean water.

- Store in well-labeled containers.

- If required get medical attention.